Evolution of the NATO Strap

What is a NATO Strap:

Traditionally, the NATO strap is a simple watch strap made of nylon webbing material and designed to weave through the spring bars of a watch case. NATO straps are available in a ton of different colors, styles, and patterns, though the foundation of a NATO strap remains almost unchanged. Rugged, comfortable and versatile, it’s not hard to see why.

Military History:

Interesting enough the NATO strap we know today draws its roots from several earlier military strap designs such as the A.F.0210, DEF-3 and Torknek-Raville (TR-900). The latter of which was a light grey (later changed to black) herringbone weave nylon strap developed to fit the US Navy strict specifications for submersible watches. However, it was the AF0210 that set the first standards for a strap. It was first introduced in 1944 and issued for tropical conditions due to the deterioration of the traditional leather straps. It was a canvas strap with black selenium dioxide treated buckles and loops. Its single-pass design ensured that it fitted quickly and easily under the fixed bars of a watch. Despite predating the DEF-3, TR-900, and the NATO straps, the A.F.0210 strap remained in service for several decades until it was retired in February 1980.

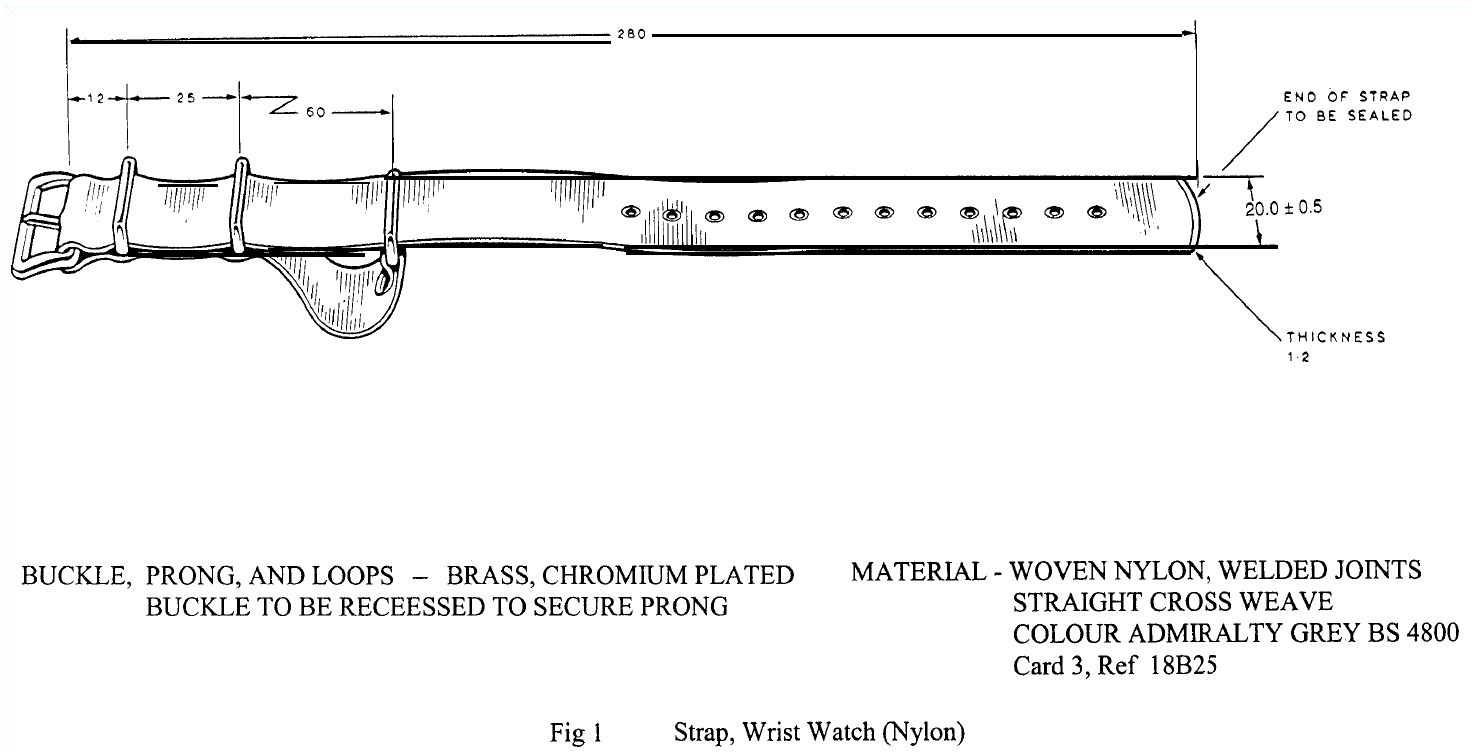

This leads us to the NATO, and contrary to what the name implies, the straps were not specifically made for the North Atlantic Treaty Organization (NATO). The strap in fact debuted in 1973 under the British Ministry of Defense Standard (DefStan) 66-15. Simply titled, “Strap, Wrist Watch” it was as a rugged and durable alternative to the more traditional leather, canvas and cotton straps. The official DefStan issued strap was made of nylon webbing and came in one color, Admiralty Gray, and one width, 20mm. The buckle and keepers were chrome plated brass and were heat-welded rather than stitched into place. Before the strap was issued to a soldier, they first had to submit a G1098 form, which aptly led to its first nickname, the “G10.” When the strap became more widely adopted, the name “NATO” strap took hold, making reference to its NATO Stocking Number (NSN).

So what about all the color variations you might wonder. Well, from the earliest time from which soldiers fought in organized companies, forces have most often possessed some sort of visible insignia to differentiate one another on the field of battle; serving as a rallying-point for the soldiers and/or indicating the position of battlefield leaders. This notion was reflected within the British military in the fashion of ribbons, patches and stable belts designed based on their Regimental battle flag or colors. The latter tradition is where we find the origins of color variations for NATO straps.

Stable belts were originally worn by the cavalry in the working dress uniform worn for stable duties. Yet, in the 1950’s they spread to all branches of the armed forces, adding a dash of color and individuality to the otherwise bland khaki working uniforms. Initially they were opposed by many senior officers, who saw them as too individualistic, but due to Regimental rivalry they soon became accepted throughout the forces. The availability of woven nylon in various colors soon led to British Military Regiments ordering NATO straps in regimental colors from specialty outfitters. Today, every Regiment of the British Army has its own stable belt, together with its own NATO strap… to go with the regimental tie of course.

Function:

We covered the components of the NATO strap, but what is it about the design that makes this simple nylon strap function so well for military use. Well, the answer to this is really two-fold, the first of which is how the strap is mounted to a watch case. The long end of the strap is has an open end and is designed to weave through the spring bars of a watch case. This method of mounting the watch serves as a security measure should one of the spring bars break, the case will still be secured by the other spring bar. The second key feature is the addition of a second shorter strip of nylon with a keeper at its end through which the main part of the strap passed through after being looped through the case lugs. This created a pocket, limiting the distance the case could move on the wrist, thus making it sit properly at all times.